Blister tooling

Our expertise ranges from the design to the production of tooling for blister machines of all brands. Whether thermoforming or cold forming, we design our tooling according to the materials you use and taking into account their deformation characteristics. We work with all the leading complex suppliers and handle all materials: Coldform, PVC, PVDC, Aclar, PET, PP, Alu, ... We also have the capacity to integrate cartoning solutions.

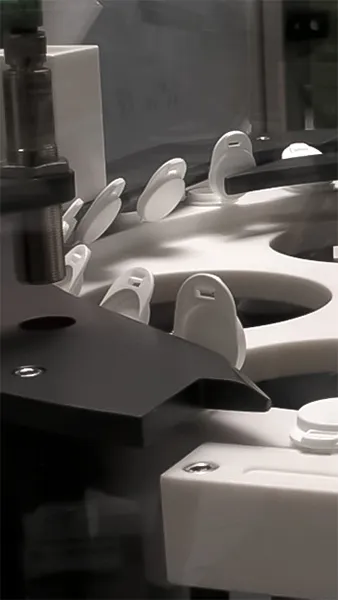

Feeders

We supply OEM-compatible tooling and we also offer our own feeding solutions, to extend the line's capabilities when product complexity requires it.

EPMO Solutions

Over the years, EPMO has developed its own feeeding solutions. The result of our experience and that of our customers, these feeding solutions have been developed to respond to ever more :

- Performance

- Reliability

- Flexibility

- Cleanability (GMP)

Combo system

The Combo system, now in its 3rd generation, is a perfect example of this.

OEM Solutions

Our expertise enables us to address OEMs: Partena, IMA, Marchesini, Uhlmann, Noack, Klockner, etc....

Primary feeder, sorting bench and dust device

The primary feeder is used to transfer products to a filling system. To which a sorting bench can be added, which allows non-conforming products (broken, stuck products...) to be removed. Dust collector device can also be considered for very dusty tablets.

Spare parts

EPMO supplies new spare parts, and reconditioning services for blister machines:

- Cutting tools

- Heating plates

- Embossing punches

- Feeding tubes

Additional devices

Desiccant cutting and sticking device

This system enables pellets of desiccant to be cut out and incorporated into the blister before sealing. Such as Activ-BlisterTM and fishbone. The addition of a desiccant pellet increases the lifetime of a pharmaceutical product in a blister pack.

Tube filling machine

This system allows CSP® tubes of different sizes to be opened and closed, after filling, while complying with GMP standards. This ensures that the tube remains tamper-proof until it is used for the first time.

Cosmetic tooling

In addition to our activity in the pharmaceutical industry, we offer our services to the cosmetics and wellness industry. By way of example, we develop forming moulds for lipstick machines and powder compacting tooling for make-up.

Would you like to find out more about our tailor-made solutions?

Our custom solutions means technical support and advice to provide you with solutions that boost productivity and profitability.

Contact us